Chiimutsara wekurongedza?

Ngatidzidzeikurongedza mutsara wezvigadzirwa zvehupfuiri, kuti inoshanda sei, izvo zvigadzirwa zvinofanirwa kushandiswa, uye zvimwe zvakawanda.

A kurongedza mutsara wezvigadzirwa zvehupfundeye yakabatana nhevedzano yemidziyo nemichina inoshandiswa kushandura zvinhu kuita yavo yekupedzisira yakarongedzwa fomu mukati mekurongedza. Iyo inowanzo sanganisira assortment yemashini otomatiki kana semi-otomatiki anogadzirisa akasiyana siyana ekurongedza, anosanganisira kuzadza, capping, kunyora, uye kuisa chisimbiso. Yakasiyana-siyana poda zvinhu zvakanakira kurongedza mitsara.

Packaging line yezvigadzirwa zvehupfumaindasitiri: Chikafu uye zvinwiwa kurongedza mitsetse, mishonga yemishonga, zvinhu zvekuchengeta munhu, zvinhu zvemumba, uye mamwe maindasitiri.

Seti A kurongedza mutsara wezvigadzirwa zvehupfu.

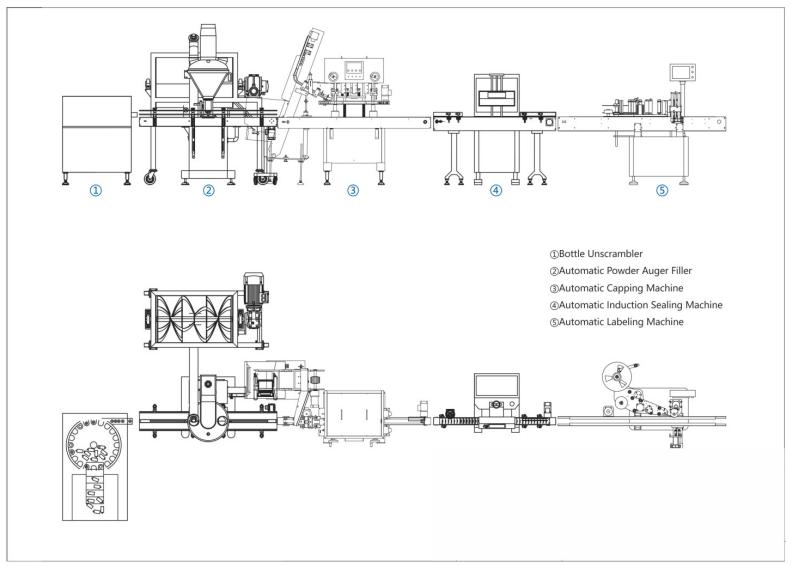

Bhodhoro unscrambler + auger filler + otomatiki capping muchina + foil yekuisa chisimbiso muchina

Seti B kurongedza mutsara wezvigadzirwa zvehupfu

Bhodhoro unscrambler + auger filler + otomatiki capping muchina + foil sealing muchina + labeling muchina

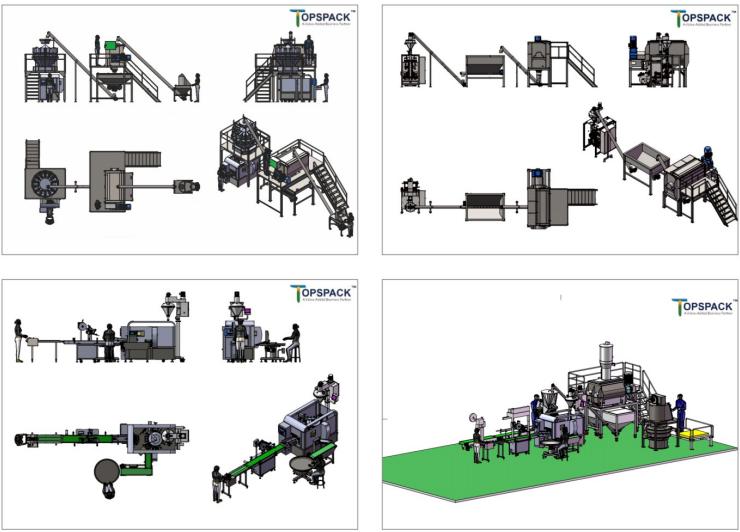

Isu tine zvakare seti yakasiyana yehupfu hwekusanganisa uye kurongedza system:

Inogona kubatanidzwa nebhodhoro unscrambler + otomatiki poda auger kuzadza + otomatiki capping muchina + otomatiki induction sealing muchina + otomatiki labeling muchina.

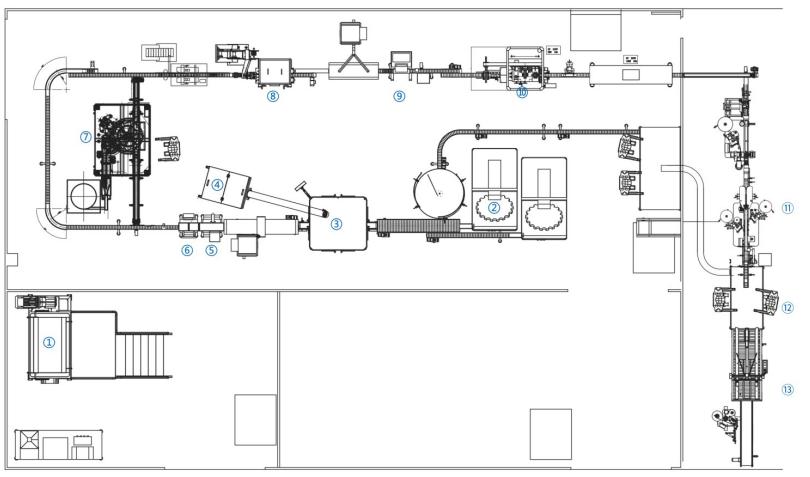

Inogona kubatanidzwa zvakare nemuchina wekusanganisa + bhodhoro unscramble + dual musoro auger filler + screw conveyor + simbi detector + uremu cheki + otomatiki rotary capping muchina + otomatiki mutsara capping muchina + induction sealer + sleeve labeler + yakawanda-inoshanda labeler + yekurongedza tafura + katuni muchina.

Izvo zvinonyanyozivikanwa zvikamu zve amutsara wekurongedzazvinosanganisira:

Kuzadza Machine: Uyu muchina wekuzadza unogona kuyera, kuzadza, uye kuita mamwe mabasa. Muchina uyu wakanakira kurongedza ese ari maviri hupfu hunoyerera, hwakadai sehupfu hwemukaka, uye granular illiquid zvinhu nekuda kwekugadzira kwayo, yakanyatsogadzirwa chimiro. Sezvo ichishandisa yakasarudzika auger kuzadza uye komputa-yakavakirwa-chaiyo-nguva yekutevera, zvakare inoshamisa chaizvo uye inoshanda.

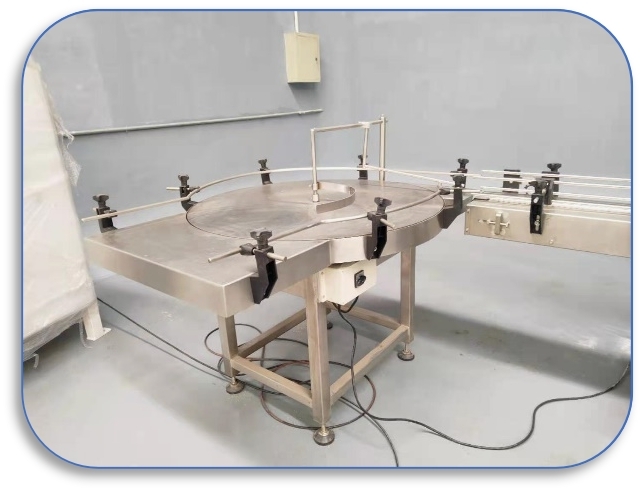

Conveyors: Vanotakura zvinhu padivi pemutsetse wekurongedza. kuvimbisa kuyerera kusina musono kwezvinhu mumichina yakawanda yekurongedza. Zvichienderana nezvinodiwa pakurongedza, anogona kunge ari mabhandi ekutakurisa, roller conveyors, kana imwe mhando.

Capping Machine: Basa remushini wekuvhara bhodhoro nderekukoira pamabhodhoro caps otomatiki. Izvi zvakagadzirirwa kuti zvishande nemapakeji masisitimu ari otomatiki. Muchina uyu unoenderera mberi capping muchina, kupesana neyakajairwa inopindirana akasiyana. Muchina uyu unoshanda zvirinani pakutsikirira zvivharo zvakachengeteka uye zvichikonzera kushomeka kwepuncturing pane inopindirana capping.

Labeling Machine: Muchina uyu uri nyore kushandisa, wakazvimiririra, uye une mutengo une musoro. Iyo ine touch screen inokurumidza kudzidziswa uye inorongwa. Pane iyo yakasanganiswa microprocessor, akasiyana ma paramita ebasa anorekodhwa kuti agonese nyore uye nekukurumidza switchover.

Nguva yekutumira: Kubvumbi-03-2024